The new peanut oil press production line developed by Aoyou Machinery and Equipment Co., Ltd.

Dear Chattogram [Peanut oil press production line] customer! You are the 124538th guest to visit Aoyou enterprise! {tyxcy} Aoyou has been committed to processing of agricultural and sideline cash crops innovation exploration and experience accumulation since its establishment, and has provided {cpxrc} [Peanut oil press production line] products to hundreds of customers!

Developing Chattogram market dependencies on high quality, Peanut oil press production line product knowledge points: The new peanut oil press production line developed by Aoyou Machinery and Equipment Co., Ltd. - Aoyou Machinery can be used for a variety of oil crops such as mustard seeds, cottonseed, soybeans, peanut kernels, tung seeds, sunflower seeds, sesame, flax, Su Zi, camellia seeds, etc.

The production line of the new peanut oil press integrates an automatic temperature control system, which can adjust the appropriate temperature for different raw materials, which is convenient to operate and simplifies the complexity of frying. Learn more and decide early, Asia grease equipment Peanut oil press production line regional product service provider--Aoyo edible oil equipment Chattogram overseas online promotion station customer service representative reminded the industry friends to pay attention to the following: In addition to feeding, there is basically no need for other operations, such as automatic temperature control, vacuum filtration, simple operation, small floor area and high oil yield. It is Aoyou Machinery Equipment Co., Ltd., the supplier of Aoyou Machinery, which can increase the customer's actual oil yield by 10-30% based on the new technology and temperature control. Make decisions with knowledge, Asia edible oil processing equipment Peanut oil press production line product supplier--Aoyo edible oil equipment Chattogram overseas customer service station customer service representative reminded industry friends to know the following: The screw oil press is advanced in design, reliable in performance, simple in operation and convenient in maintenance. It is characterized by energy saving, high oil yield, labor saving, wide in use, good in oil quality and small in land occupation.

Peanut oil press production line (supply)

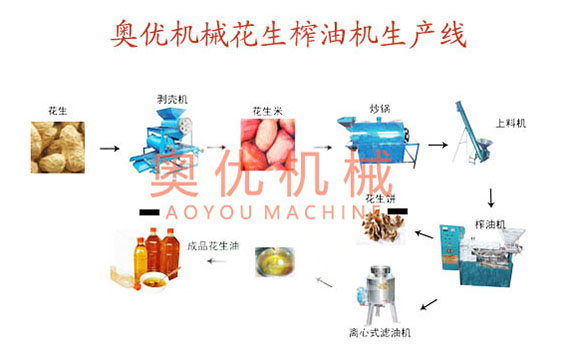

Figure 1:

Figure 2:

Figure 3:

Figure 4:

Figure 5:

Peanut oil press kit 1 (as shown in Figure 1): peanut sheller - new drum frying pan - feeding machine - new oil press - centrifugal oil filter

Peanut oil press kit 2 (as shown in Figure 2): electric conduction oil pan - new oil press - centrifugal oil filter

Peanut oil press kit 3 (as shown in Figure 3): new drum frying pan - new oil press - centrifugal oil filter

Peanut oil press kit 4 (as shown in Figure 4): drum electric frying pan - new oil press - centrifugal oil filter

Peanut oil press supporting 5 (as shown in Figure 5): closed frying pan - new oil press - centrifugal oil filter

The peanut oil press production line, the peanut oil press production line process, and the peanut oil press production line manufacturers' advantages are introduced as follows:

Chattogram friends should know this: The new peanut oil press production line developed by Aoyou Machinery and Equipment Co., Ltd. - Aoyou Machinery can be used for a variety of oil crops such as mustard seeds, cottonseed, soybeans, peanut kernels, tung seeds, sunflower seeds, sesame, flax, Su Zi, camellia seeds, etc.

The production line of the new peanut oil press integrates an automatic temperature control system, which can adjust the appropriate temperature for different raw materials, which is convenient to operate and simplifies the complexity of frying. We have been doing research and development in processing of agricultural and sideline cash crops and serving Chattogram customers, Aoyo edible oil equipment customer service representatives highlight: In addition to feeding, there is basically no need for other operations, such as automatic temperature control, vacuum filtration, simple operation, small floor area and high oil yield. Based on the new technology, our factory can increase the actual oil yield by 10-30% through temperature control. Correct decisions originated from knowledge accumulation, Asia Chattogram edible oil equipment Peanut oil press production line rest assured service enterprises Aoyo edible oil equipment enterprise network promotion sub-station customer service representative reminded Chattogram friends to know this: The screw oil press is advanced in design, reliable in performance, simple in operation and convenient in maintenance. It is characterized by energy saving, high oil yield, labor saving, wide in use, good in oil quality and small in land occupation.

Process flow of pressing peanut oil:

Cleaning - shelling - frying seeds - pressing - filtering - finished peanut oil;

Peanut oil press production line, peanut oil press production line process, peanut oil press production line manufacturer operation instructions:

(1) Cleaning and drying of peanuts: peanuts entering the oil factory inevitably carry some impurities. If you do not remove the soil, stems and leaves and other sundries carried in the flowers and fruits, they will not only affect the quality of oil and cake, but also absorb some oil and reduce the oil yield. We have been doing research and development in processing of agricultural and sideline cash crops and serving Chattogram customers, Peanut oil press production line product knowledge points: If there are sand, metal, hemp rope and other sundries in the peanut fruit, it will cause the wear of machine parts, cause production accidents and affect the process effect. Therefore, in order to ensure the smooth production of customers, impurities must be removed as much as possible. Chattogram friends should know this: For individual peanut fruits with high water content, it is also necessary to dry them for the convenience of shelling. There are many methods for cleaning, and different methods can be used according to the situation of impurities. If the impurities contained are light, such as grass, stems and leaves, the method of air separation can be used to blow off the impurities with air flow. If the impurity particles are small, the impurity can be removed by selecting. For some impurities similar in size and relative density to peanuts, if they belong to soil lumps, they can be removed by screening after being rubbed and crushed in the mud machine. If it is a ferrous impurity, it can be separated by electromagnet or magnet. The impurity content shall be below after cleaning.

(2) Shelling: The purpose of peanut shelling before oil extraction is to reduce the adsorption of oil by the shell and improve the oil yield; It can improve the processing capacity of the customer's oil press and reduce the wear of the oil press equipment; It is good for rolling billet and improving the quality of crude oil; It can improve the quality of cake and is conducive to comprehensive utilization.

(3) Heat treatment (steam frying): before frying the seeds, the frying pan should soak the peanut kernels once. Brand development Chattogram market, service connection Chattogram customers。 Peanut oil press production line key points of product knowledge: During the process of frying the seeds, the kernels should be fried until they are eight mature, kneaded by hand to achieve the separation of kernels and skins. The kernels are light yellow, the temperature is about 130 ℃, the water content is 1-2%, the cake thickness is 0.7-1.2mm, the cake is long and wrinkled, and the oil is smooth. Chattogram friends should know this: The effect of heat treatment has a direct impact on the smooth progress of the whole oil production process, the level of oil yield and the quality of oil and cake. The heat treatment process is canceled in the cold pressing process, but it needs to be pressed twice. In fact, one press is also a process of heating. The cold pressing oil yield is low and the flavor is much lighter.

(4) Press: adjust the temperature controller of the peanut oil press to the temperature required for pressing 120 ℃ - 180 ℃ (depending on the oil). Asia grease equipment regional product service provider Aoyo edible oil equipment Chattogram Peanut oil press production line overseas customer service station customer service representative Peanut oil press production line product knowledge: Turn the heating switch to the heating position of the main machine to heat the machine. At this time, the green light on the temperature controller is on and the red light is off. When the machine temperature rises to the set temperature, the red light is on and the green light is off. The machine temperature is automatically controlled and maintained at the set temperature. When the temperature is low in winter, Turn the heating switch to the full heating position of the main engine to raise the temperature of the oil pan and facilitate the oil retention. There is a certain relationship between pressing time and oil production efficiency. Aoyo edible oil equipment professional production quality, customer assured, remind customers in the Chattogram processing of agricultural and sideline cash crops domain to know more about Peanut oil press production line product knowledge. It is generally believed that the peanut oil press has a long pressing time and a slow oil outflow, but the pressing time cannot be too long, otherwise the heat loss will be more, which will affect the oil production efficiency and production capacity. Therefore, on the premise of meeting the oil production efficiency, shorten the pressing time as much as possible. Insist on manufacturing first-class products, Aoyo edible oil equipment Peanut oil press production line product information points: The residence time of the material embryo in the press chamber mainly depends on the rotation speed of the screw shaft, followed by the degree of newness of the screw press ring and the thickness of the cake. For some oilseeds with high oil content, the pressing time can be appropriately extended, and the appropriate rotation speed should be selected.

Asia grease equipment regional product service provider Aoyo edible oil equipment Chattogram Peanut oil press production line overseas customer service station, based on the advantages of processing of agricultural and sideline cash crops industry, focuses on "win-win cooperation" processing of agricultural and sideline cash crops Peanut oil press production line service provider -- Aoyo edible oil equipment's business philosophy can be summarized into eight words "honesty based, win-win development". Aoyo edible oil equipment has always implemented this concept well for both its internal employees and its external Peanut oil press production line partners, thus gaining long-term good business reputation and cooperative relations in the processing of agricultural and sideline cash crops field and promoting the stable development of Aoyo edible oil equipment.

{ssxcy} In the era of intelligent manufacturing, the craftsman spirit is not outdated, and its essence is to do things wholeheartedly. Asia grease equipment regional product service provider Aoyo edible oil equipment Chattogram Peanut oil press production line overseas customer service station, For many years, Aoyo edible oil equipment has focused on the processing of agricultural and sideline cash crops field and polished the "craftsman" level talents on Peanut oil press production line products! {tyxcy} Congratulations to all Chattogram friends {xnzf}

{liuyanyindao}

{dy20}

ab153529543@gmail.com

ab153529543@gmail.com  +86-132-9090-8300

+86-132-9090-8300